Truck Crop Yield Monitoring / Mapping

Monitor - KB Manufacturing of Fisher, MN, provides the load cells and hardware for a truck weight monitoring system.

Mapping - GK adds the PC software to make a complete yield monitoring / mapping system which has been tested for over 16 years.

Mapping - GK-John Deere Yield Mapping Interface connects to Deere displays to do Yield Mapping on our Deere system.

The Hardware - Yield Monitor

To purchase or find out more about the hardware for the Potato & Sugar Beet Yield Monitor, visit the KB MFG. website to below.

For support on the hardware and monitoring system, contact Scott Knutson.

PC Software - Yield Mapping

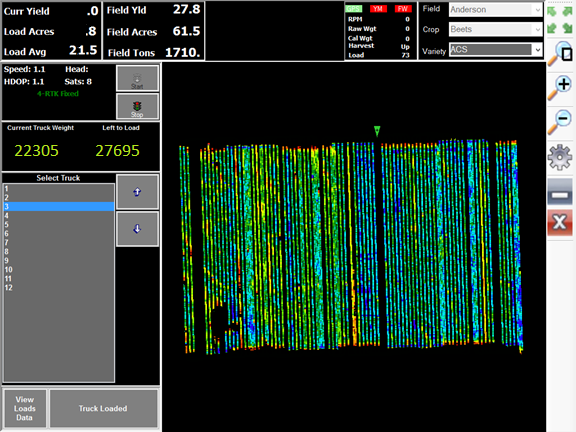

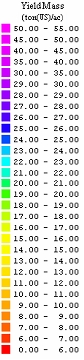

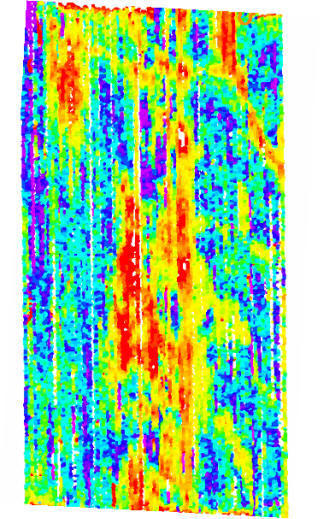

Beet Yield Mapping for the Tablet PC

- Select the “Field” in the upper right box

- Select the “Crop” in the upper right box

- Select the “Variety” in the upper right box

- Click “Start”

- View harvest information in the lower right box

GK-John Deere to KB Yield Interface System

Beet Yield Mapping for John Deere 2630 & Compatible 4600 series Monitor

NOTE: Customer must have:

- John Deere Yield Documentation, Specialty Crop (1120) ISO application controller

- KB MFG Truck Crop Yield Monitoring hardware with (2012 or newer Cal Chip).

- GK Interface harness and interface box will plug into existing wiring.

- Setup the ISO components on the John Deere Monitor.

- Mapping and data collection will happen on your 2630 or 4600 series display.